In the competitive world of multi-level marketing (MLM), effective inventory and vendor management is often the hidden linchpin of scalability, profitability, and distributor satisfaction. Whether your model is more B2B (distributors buying in bulk from you) or B2C (sold directly to end customers through your network), the challenges of demand variability, multiple touchpoints, and complex supply chains must be addressed with modern approaches.

Here’s a structured deep dive into how MLM businesses can streamline vendor and inventory management, backed by real data, emerging trends, and practical tactics.

MLM companies face three key pain points (beyond what typical retail or wholesale operations do):

If mismanaged, these issues lead to stockouts (lost sales), overstock (write-offs, expiration), friction in distributor relationships, and poor brand reputation.

A 2025 article by ePixel highlights that strategic inventory management is not just logistics — it’s a competitive weapon in MLM structures.

When your MLM operation incorporates B2B and B2C flows (i.e. distributors buy bulk from you, but also sell to end consumers), you must juggle two different inventory mindsets:

| Feature | B2B / Distributor Supply | B2C / Consumer-Facing |

|---|---|---|

| Order size & frequency | Large, periodic bulk orders | Small, frequent orders |

| Demand volatility | Smoother, contract-driven | Seasonal, trend-driven |

| Service expectations | On-time delivery, consistency | Fast fulfillment, real-time stock visibility |

| Inventory strategy | Just-in-Time (JIT), safety stock buffers | Faster turns, lean inventory |

As Simplisales notes, B2B inventory management requires strong supplier relationships, bulk procurement, and predictability, while B2C demands agility, omnichannel integration, and responsiveness.

Thus, in MLM you must unify both: ensuring your distributors are well-stocked (without overcommitting), while your end-consumer pipeline remains responsive and low friction.

Here are concrete strategies and tactics to build robustness:

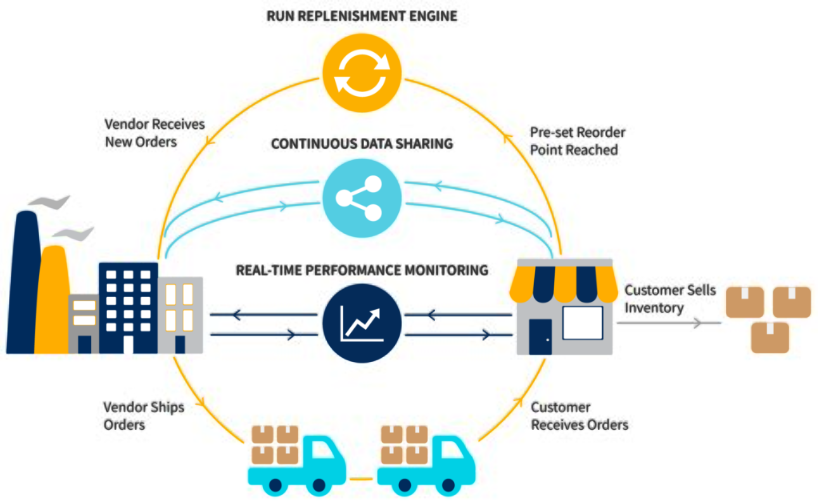

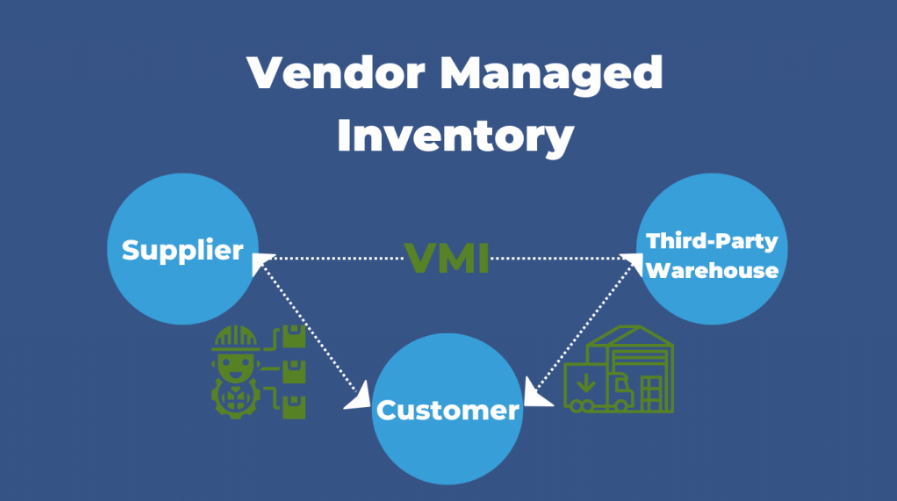

With VMI, suppliers/vendors monitor and replenish inventory at your network (warehouses or even distributor nodes) using shared data. The vendor has access to your inventory and sales data and plans replenishment accordingly. This reduces inventory carrying and stockouts. NetSuite + Adobe for Business

Best practices in VMI (per Extensiv):

In MLM, you can push VMI relationships upstream: your product manufacturers or contract manufacturers could manage inventory at your central or regional warehouses using your network sales updates — lowering your burden.

One of the biggest pitfalls in MLM is distributed “shadow inventory” — stock sitting with distributors, unrecorded or delayed in updates. Modern MLM software systems now offer:

When distributors place orders, the system immediately deducts inventory, recalculates safety stocks, and triggers replenishment if thresholds are crossed.

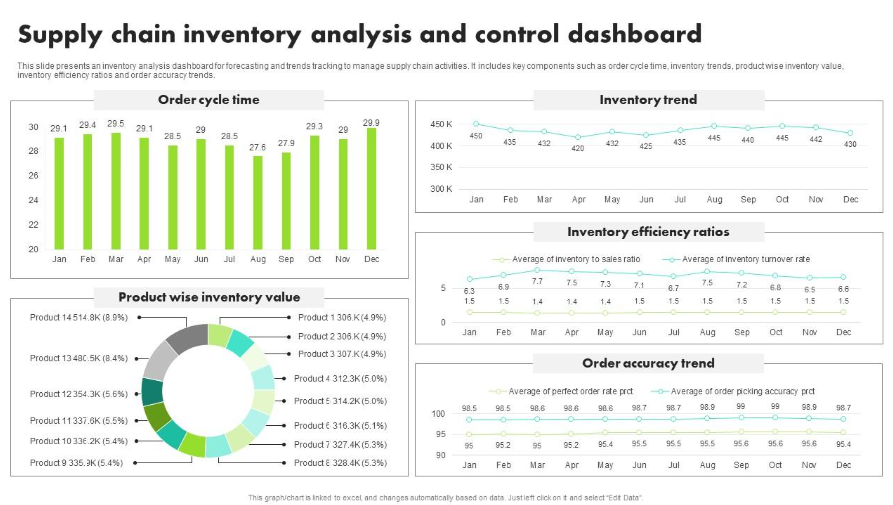

From the 2024 Netstock Benchmark Report:

In MLM, you can adopt velocity-based inventory strategies: track how fast SKUs move through the network and adjust safety stock dynamically, rather than fixed rules. Slow-moving SKUs get tighter caps; fast-moving ones get more buffer.

Distribute inventory smartly:

You must hold vendors accountable with metrics such as:

These help you prune underperformers, renegotiate terms, or shift to alternative vendors. (Data-Mania, LLC covers these vendor metrics well)

As McKinsey’s 2024 B2B survey shows, top B2B players are investing in omnichannel and digital buyer experiences.

In MLM, this translates to enabling your distributors to see:

By reducing friction in the order process, you reduce delays, order errors, and over/under-stocking.

Supply chains remain volatile (geopolitical tension, raw material swings). The 2024 Netstock report emphasizes the importance of supplier reliability and nearshoring trends to reduce risk.

For MLM:

To help you gauge performance, here are some relevant benchmarks and data points:

In the MLM space, though less public, anecdotal experience suggests:

Use your network data to calculate:

Compare those with internal goals and industry peers.

Here’s a suggested phased rollout:

| Phase | Objectives | Key Activities |

|---|---|---|

| Phase 1 – Baseline & Audit | Understand current state | Audit existing inventory, vendor contracts, order flows, discrepancies. Identify SKUs with high volatility or chronic issues |

| Phase 2 – Software & Visibility | Deploy or upgrade centralized MLM/inventory software | Integrate real-time tracking, dashboards, reorder alerts, commission linking |

| Phase 3 – Vendor Integration / VMI pilots | Begin partial VMI with trusted suppliers | Start with 1–2 SKUs or 1 regional warehouse; test sharing data, auto replenishment |

| Phase 4 – Optimization & Analytics | Apply AI/demand forecast, dynamic safety stock | Use historical data, adjust buffers and reorder rules |

| Phase 5 – Scale & Feedback Loop | Roll out across SKUs and network | Develop vendor scorecards, continuous improvement, refine rules |

During rollout, don’t underestimate change management: distributors and internal teams must be trained, incentives aligned, and communication frequent.

Here’s what’s shaping the future of vendor/inventory management that MLMs should pay attention to:

These trends will become more accessible as MLM businesses scale, making what seems “enterprise-only” today typical in 2–3 years.

Effective vendor + inventory management is mission-critical for MLM business models, especially hybrids of B2B/B2C.

Vendor and inventory management in MLM involves coordinating product sourcing, warehousing, and distributor stock levels to ensure efficient product flow and timely delivery across the network.

By adopting centralized inventory software, using real-time stock tracking, and implementing vendor-managed inventory (VMI) models to reduce manual errors.

Trends include AI-driven forecasting, blockchain traceability, IoT tracking devices, and regional sourcing (nearshoring) to cut lead times and improve reliability.

Automation reduces human error, synchronizes distributor data, and helps manage multi-warehouse operations efficiently — saving cost and improving distributor satisfaction.

Platforms like NetSuite, Zoho Inventory, and specialized MLM ERP software provide end-to-end vendor, order, and inventory visibility for hybrid B2B/B2C networks.